- Use of combined devices in almost all kind of fluids

- Detection of levels and temperature in shipbuilding, off-shore, petrochemical and chemical sector, plant construction, mechanical engineering, hydraulic power packs, cooling systems, potable water treatment, food and beverage industry, power plants and other power systems.

- Two functions, level and temperature, in one device

- Sliding tube optionally in stainless steel or brass.

- Use in high operating pressures possible.

- Individual solutions of connection, mounting, material, function...

- Temperature output 4-20mA, or 0-10V

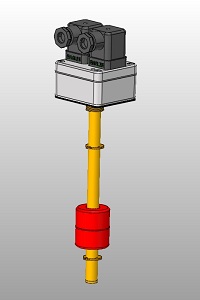

S106L

- Sliding tube in brass or stainless steel

- Connection aluminum housing with plug connection

- Float material selectable

- Analogue temperature output 4-20mA

- ...

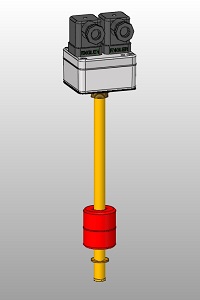

S110L

- Sliding tube in brass or stainless steel

- Connection aluminum housing with plug connection

- Float material selectable

- Analogue temperature output 0-10V.

- ...

A float switch with analog temperature measurement is a device typically used in tanks or containers to monitor liquid levels while simultaneously measuring the temperature of the medium. It combines two functions in one device: a float switch for level detection and analog temperature measurement. The device is equipped with a microcontroller for signal conversion, which converts the resistance signal into an analog output signal, typically in the form of a 0-10V or 4-20mA signal.

Operation Principle

The operating principle of a float switch based on a Reed contact relies on the use of a Reed contact as a switching element. A float switch consists of a buoyant body, also known as a float, which floats on the liquid surface. The buoyant body is equipped with a magnet. When the liquid level changes, the buoyant body moves up or down accordingly. When it reaches a certain fill level, the magnet approaches the Reed contact. The Reed contact consists of two ferromagnetic contact leaves placed inside a glass bulb. These leaves are separated by a small air gap. When the magnet of the buoyant body reaches the Reed contact, the magnetic field attracts the ferromagnetic leaves and brings them together. This action closes the contact leaves, completing an electrical circuit. This closed circuit can be used to send a signal, such as triggering an alarm or controlling a motor.

Analog temperature measurement is performed using highly accurate temperature sensors such as PT100 or PT1000. These sensors operate on the principle of changing the electrical resistance of a metal based on temperature. A PT100 sensor consists of a platinum resistor that changes its resistance value as the temperature rises. Similarly, a PT1000 sensor functions in the same way, except that its resistance in ohms is 1000 times greater than that of PT100. PT sensors are capable of providing very precise and accurate resistance values directly related to the temperature of the liquid or medium in contact. These analog resistance values are then converted into temperature values and displayed through an appropriate measuring device or evaluation circuit. Temperature values can also be transmitted to control and regulation systems to monitor and, if necessary, control and regulate the temperature within the system.

Advantages

- Reliable Level Detection: Float switches are robust and proven sensors for level detection. They provide a reliable way to accurately monitor the fill level in a tank or container and can be used in various liquids and environmental conditions.

- Accurate Temperature Measurement: Analog temperature measurement provides precise temperature data for the medium in a tank or container. This allows for precise control of process or operating conditions and can help detect potential issues early.

- Combined Functionality: The advantage of a float switch with analog temperature measurement is that it can monitor two important parameters simultaneously. This saves space, costs, and effort as there is no need for two separate sensors.

- Easy Installation and Maintenance: Float switches are typically easy to install and require minimal maintenance. They have no moving parts inside the liquid container, reducing the possibility of blockages or damage.

- Robust Design: Float switches are often made from durable materials and can be used in challenging industrial environments, including corrosive or aggressive liquids.

- Quick Response: Float switches typically respond quickly to changes in level or temperature, allowing for timely alerts or control.

- Adaptability: There are various designs and sizes of float switches available to meet the specific requirements of different applications, making them versatile.

- Safety: Continuous monitoring of level and temperature helps identify and prevent potential hazardous situations, enhancing the safety of personnel and facilities.

Applications and Industries

Industrial Automation

In automated manufacturing processes, float switches with temperature measurement are often used in liquid tanks and containers to monitor the level and temperature of cooling or lubricating fluids in machinery and process equipment. This enables precise control of fluid supply to ensure smooth operation and optimal process conditions.

Mechanical Engineering

In machines and equipment that work with fluids, float switches with temperature measurement are frequently used in hydraulic or lubrication systems. They monitor oil levels and temperature to ensure proper lubrication and cooling of machines, contributing to extended machine life and reduced downtime due to lubrication issues.

Chemical and Pharmaceutical Industry

In these industries, float switches with temperature measurement are used in storage tanks and reactors to monitor the level and temperature of chemical substances. This enables the safe handling of chemicals and controlled reaction conditions.

Power Generation

In power plants and energy storage facilities, float switches with temperature measurement are used to monitor fuel tanks and cooling systems, ensuring efficient power generation and the safe operation of facilities.

Food and Beverage Industry

In food processing and beverage production, float switches with temperature measurement are used in tanks and containers to monitor the level and temperature of ingredients, products, or cleaning solutions.

Water Treatment and Wastewater Management

In wastewater treatment plants and water treatment facilities, float switches with temperature measurement are used to monitor levels and temperatures in various tanks and basins, ensuring the smooth operation of water treatment processes.